Product Description

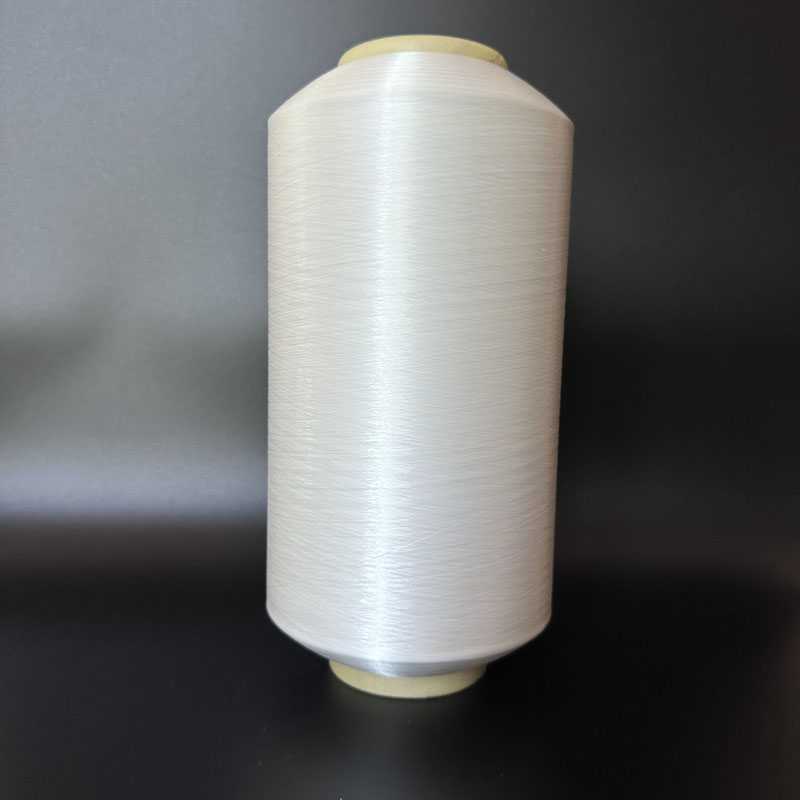

Letswin Textile Heat-Bonded Nylon Fiber 70D

70D/8F (D=denier ; F=filament )

Specs: 70 Denier

78 dtex

Melting Point: 110℃

Grade: AA

N.W: 1kg/units

Packing: 15units / CTN

Heat-Bonded Nylon Fiber, also known as fusible yarn, fusible adhesive yarn, is used in textiles, footwear, industry and products. It is made of low-melting polyamide (nylon) or polyester, and the melting point can be controlled between 85°C and 180°C by adjusting the characteristics of the raw material.

At normal temperature, the thermal fuse is woven with other fibers into a fabric, and then pressure is applied to the fabric under dry heat or wet heat. When the temperature is higher than the melting point of the thermal fuse, the thermal fuse gradually melts. At this temperature, conventional other fibers remain unchanged and are thus bonded together by thermal fuses.

Compared with ordinary fibers, it melts at a very low temperature, so that it does not damage the fibers or fabrics, and it is a highly functional yarn that provides the desired adhesion, strengthens the cohesion of the fibers, and imparts shape stability. Therefore, the thermal fuse can replace chemical adhesives such as glue, avoiding the pollution of volatile matter and powder layer, and is environmentally friendly and non-toxic; at the same time, it saves the process flow, improves production efficiency, and reduces downstream production costs.

Features

High-quality raw materials, all imported raw materials are used.

The melting point is produced in strict accordance with the standard melting point.

The color is sliced in primary colors, which has better color fastness, chromaticity and physical properties than masterbatch dyeing. ·In terms of performance, it feels softer and more comfortable, fuller in elasticity, firmer in strength, stronger in adhesion, better in wear resistance, better in shaping effect, faster in solidification, resistant to washing and dry detergent, breathable and waterproof, and free of environmental pollution.

Application

Letswin Textile provides Japanese Heat-Bonded Nylon Fiber 70D for: lace webbing, 3D shoe upper weaving, sewing thread, Bondi thread, trouser cuff, soft yarn curtain, vertical curtain, high-strength webbing, wool carpet, padding , Weaving to prevent curling and loose edges, automotive lining and other industries.

Manufacture Ability

Advanced, clean and tidy workshops

The advanced polyreaction equipment

PTG Tank

+86-13500092058

+86-13500092058

E-mail

E-mail